Countless businesses still depend on human workers to get things done at a time when automation is constantly moving closer to becoming the standard in most industries. Whether it’s manufacturing products or building structures, there will always be situations where manual labor is the only option. To improve the efficiency of a human workforce, however, companies can equip their people with a variety of power tools.

There are various kinds of power tools that can be used to perform tasks, but all are designed to speed up work and improve results. For example, tools such as power drills, sanders, shears, and circular saws are essential for manually machining components, while power wrenches, nail guns, and drivers are perfect for assembling components. Today’s successful manufacturers and construction companies will always have a collection of power tools ready to be used by their workforces.

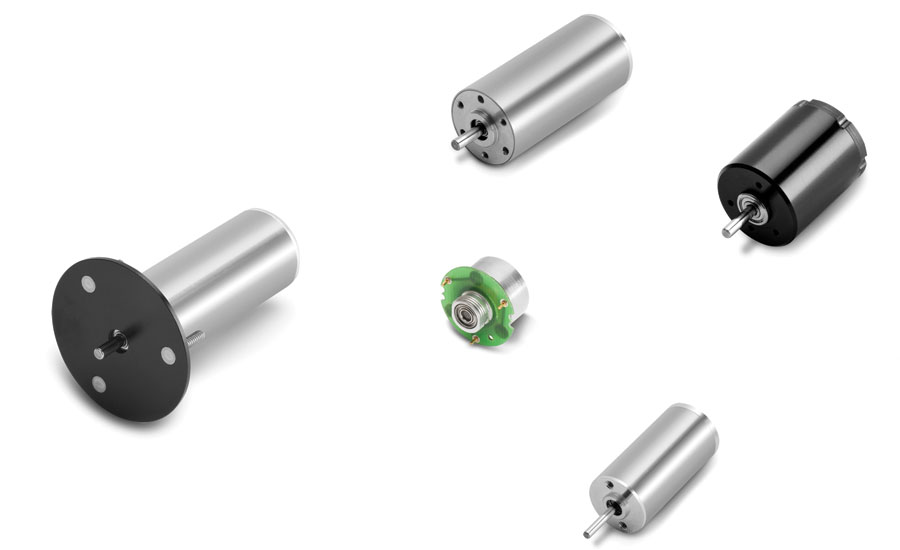

To ensure their reliability, many effective power tools feature high-quality brushless DC motors. And in order for power tools to work well and meet industrial standards, these tiny powerhouses must have the following characteristics.

1. Speed – Any motor can spin if given enough power, but micro-motors found inside power tools are designed to spin up to several thousand RPM for better speed and consistency. For example, a hand drill that moves too slow will take too long to bore through even the thinnest materials, while powered circular saws will just “bite” into the material if the blade doesn’t spin fast enough, causing jagged cuts.

2. Torque – Because power tools are used when working on tough materials such as metal or wood, the micro motors that make them work should have enough torque to be effective. This is especially true for tools such as power shears and drills used for metal and concrete.

3. Durability – Many industrial applications of power tools are very demanding. A circular saw that features a conventional motor can get damaged by sawdust getting into the motor, while power tools used in construction must be able to withstand harsh outdoor conditions. Micro motors used for power tools are designed to be durable.

4. Weight – Because power tools are hand-held by design, every component must be lightweight. This is why the best power tools are equipped with brushless dc motors, which boast a lot of power for their size. Having a lightweight motor reduces fatigue when the power tool is used for extended amounts of time. It also makes the tool easier to control.

5. Size – Aside from being lightweight, a micro motor’s diminutive size also adds to the overall portability and ergonomics of a power tool. Without bulky components, a power tool can afford to have more ergonomic profiles, allowing the user to have even more control when using it.

6. Multi-speed Control – By having multiple gearboxes, micro motors allow power tools to operate at different speeds. This multi-speed function is a valuable feature in most power tools because having the option to work on low or high settings provide a lot more variety than single-speed options.

7. Energy Efficiency – High-quality power tools feature micro motors that boast excellent energy efficiency. Energy-efficient motors are especially important for battery-operated power tools since running out of power might call for frequent battery changes or several hours of charging. Energy-efficient power tools are also great for bringing down a company’s energy consumption and electricity bills.

While automation is getting more and more popular, it may take a very long time before people can fully rely on robotic solutions for industries like construction or even manufacturing. Until then, power tools and the micro motors that make them work will remain essential in various industrial applications.

More Stories

Check out the Top iPhone XR Specs Before Buying the Affordable iPhone

What Should I Look For in a Bluetooth Speaker?

A Skin That Matches Your iPhone 6s Plus